Technical datasheet

- Green field (new facility)

- Filling B06 - B15 and B38 KG cylinders

- Capacity of 20,000 cylinders per month

- Possible future extension

- Surface area of 4,000 m2

Filling container

- 3 filling scales

- Weight control

- Emptying and (un)screwing of valves

Ancillary facilities

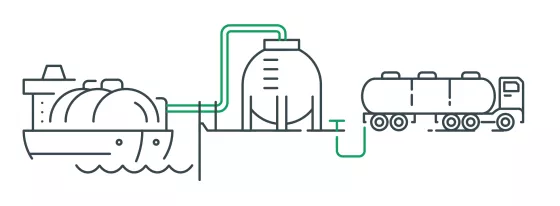

- 35 T tank

- Pump house and truck unloading station

- Technical container (Air / Electricity)

Services

- Discussions with the Customer to identify the targets

- Basic studies / Detailed studies

- Supply of equipment

- Blank tests in the workshop

- On-site assembly drawings

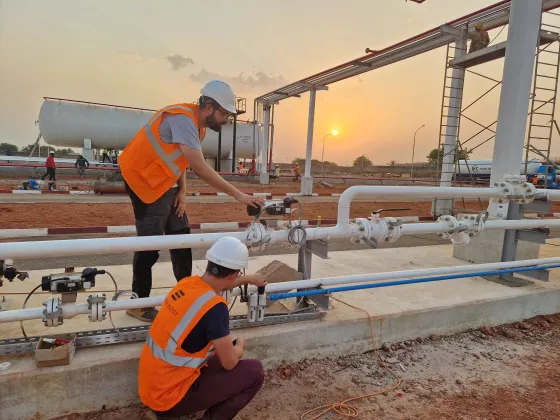

- Help with assembly and commissioning

- Help with extension

A quick and easy solution to implement

The challenge with this type of project lies in thinking about the land chosen for the filling plant and optimising the surface area used, while complying with current regulations. The aim is to reduce the cost of earthworks and civil engineering.

The studies carried out by SALTA ENERGY tailor the installation to the Customer’s production requirements. These also help us fully understand the different components and how they need to be put together.

During the construction phase, we help the Customer with the assembling of the installation in accordance with the technical requirements.

Once the work is finished, our technicians visit the site to start installation with the Customer and help him get to grips with their new tool and the first LPG cylinders to be put on the market in Kampala.

As part of the PROCARE service, we have helped the Customer to develop its plant thanks to studies and supplies intended to extend storage and instal tools for stock management.