Technical datasheet

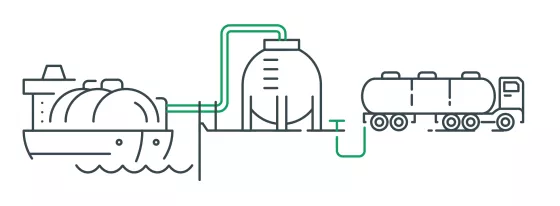

- Revamping (complete renovation of the depot)

- Total capacity of 60,000 m³

- Site continues operating throughout the project

Facilities

- 14 storage tanks

- Stored products = AGO, HFO, MSP, IK

- Complete gauging system

- Overfill protection

- Supervisory Control and Data Acquisition (SCADA)

Services

- Basic design studies / Detailed studies

- Supply of equipment

- Factory acceptance test

- Grouping and inspection

- Packaging and DAP delivery, including customs clearance

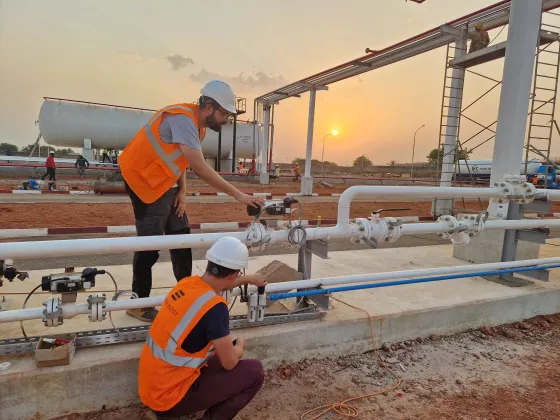

- Assembly and installation

- Commissioning

The starting point for data management

Renovating means thinking about what is already there. The project therefore starts with a thorough visit to the site to gather the necessary information. This also provides an opportunity to talk to the whole team in charge of the operation, to understand their habits, their expectations and the restrictions that they face.

The first challenge of this project is to offer supplies DAP, including, at the Customer’s request, all the work involved between our workshops and the destination site, including customs clearance.

The second challenge involves making sure that the stock management system is working properly, by carrying out factory tests and on-site checks, using the information calculated by the system and the data measured manually, while constantly adjusting the product levels in the tanks

The third challenge lies in working on a site that is in operation and guaranteeing that the Customer’s activities will continue uninterrupted.

Thanks to its turnkey projects, SALTA ENERGY provides a guarantee that the facility will operate smoothly, on time and on budget for the Customer.