Technical datasheet

- Land rehabilitation

- Production of 250,000 cylinders per month

- Filling B06 - B12 - B38 KG cylinders

- Future extension to be planned

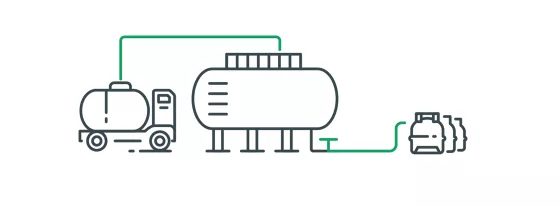

Facilities

- 200 T storage

- Automatic filling line

- Installation of a fire protection system

- Utilities: electricity and compressed air

- Gauging and detection system

- Supervision and automation system

Services

- Basic design studies / Detailed studies

- Supply of equipment

- Grouping and inspection

- Packaging and CFR delivery

- Technical coordination and management

- Commissioning

An optimised, comprehensive EPC service

A successful project is one that reaches its conclusion without any unpleasant surprises.

When a customer wants to create a new filling plant, he is restricted by his budget and his schedule. As the company responsible for engineering, supplying equipment, technical coordination of the construction teams and commissioning, we make a point of supporting the customer throughout the project.

The site chosen for the filling plant presents unique challenges, as it is a former UN site. Land rehabilitation with a view to creating a functional site for the new plant requires specific expertise, which we are managing to provide.

Respecting deadlines and budgets is paramount at SALTA ENERGY.

By using full 3D modelling from the design phase onwards, we can accurately determine the quantities of materials required in record time, guaranteeing that deadlines are met and resources are managed efficiently.

In order to optimise the customer’s costs, we are also designing a customised LPG stock monitoring system. We firmly believe that our technical know-how is the key to optimising our customers’ costs, by customising the size of their facilities.