Technical datasheet

- Revamping (replacing what is already there)

- Filling 1kg cylinders (LPG-Propylene)

- Capacity of 300 cylinders per day

Facilities

- Stationary filling scales

- Stationary control scales

- LPG instruments and valves

- Product regulation

- Electrical equipment

- Automatic zone management

Services

- Discussions with the customer to define their

requirements - Search for companies specialising in ATEX filling

- FMEA meetings and risk analysis at the customer’s premises

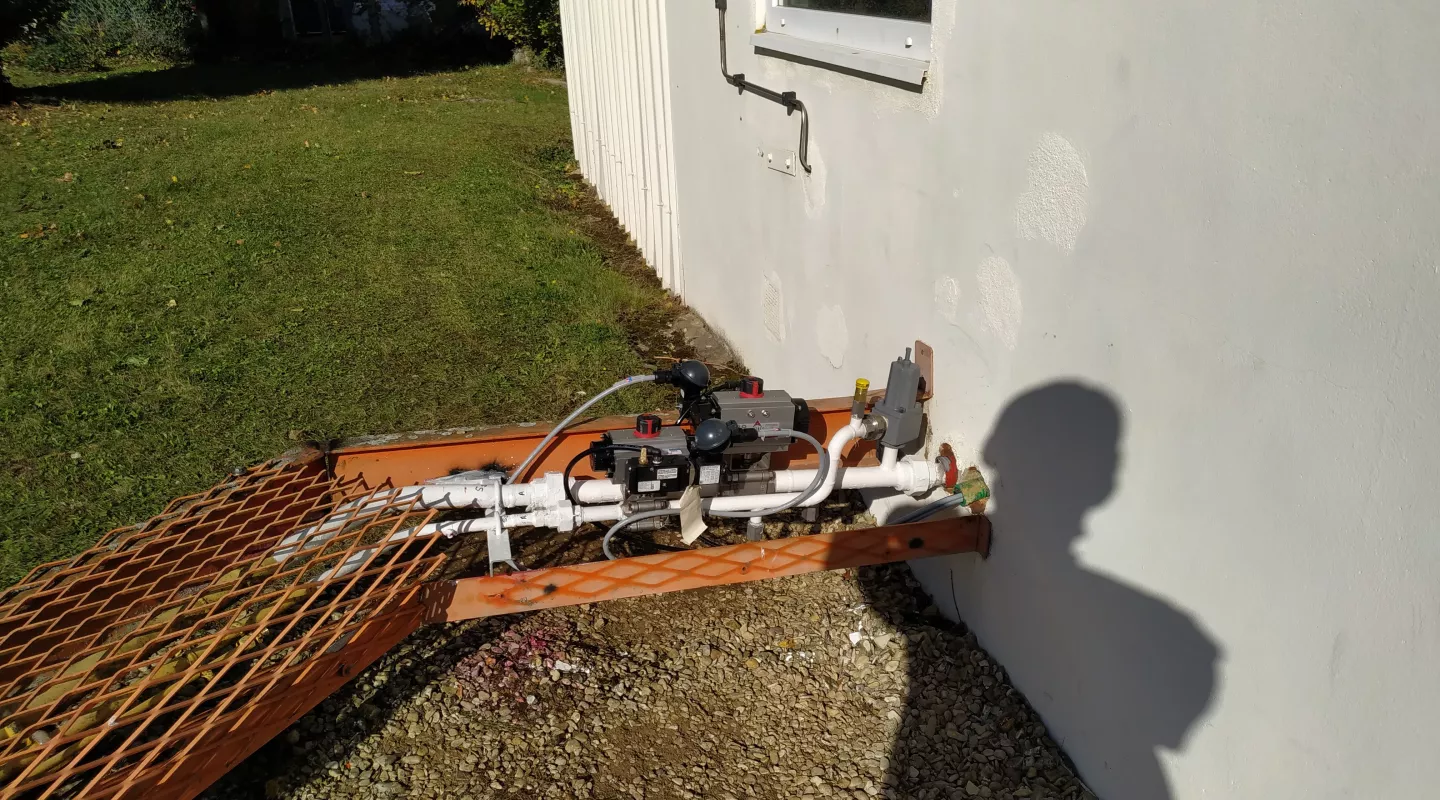

- Dry-run assembly and testing in the factory

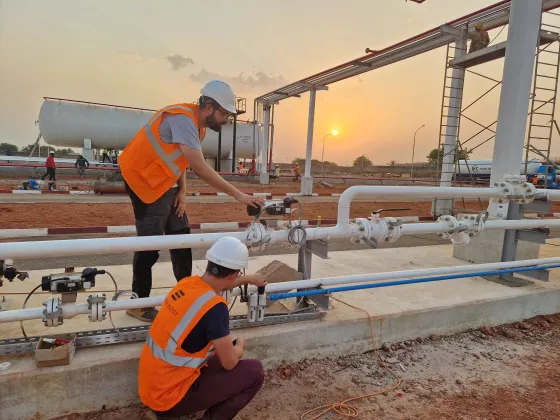

- Installation, commissioning and training

A PROJECT DESIGNED FOR ON-SITE

EFFICIENCY

The LPG market is often seen as a niche market. The case of Kyrene, a propylene-based LPG, is proof of this. There is only one facility like this in France, and the work to replace the equipment has to be carried out in a very short space of time if demand is to carry on being met.

Defining the project properly, taking the existing line into account, is the most important phase in getting the project off the ground. The client’s professionalism, combined with SALTA ENERGY’s project management experience, mean that nothing is left to chance.

Technical meetings to discuss the process, the safety of the facility and the phasing of the work soon allowed us to outline the project and define the boundaries for everyone’s responsibilities.

To guarantee speedy implementation on-site, all interaction with suppliers is carefully analysed by SALTA ENERGY. Prefabrication and blank tests in the factory are key to this project.

Working closely with the operator, work is being carried out to replace the entire line. The impact on production is under control.

Getting up and running is easy: final adjustments and training can be carried out when the first bottles are filled.